Design & Engineering

Major design standards under practice are ASME (Section I, Section VIII Div. 1 & 2, ASME PVHO-1, ASME B31.1 and ASME B31.3), API650 & API620, TEMA, EN13445, EN14015, EN13385, BS, CEMA, AD Merkblatt & others.

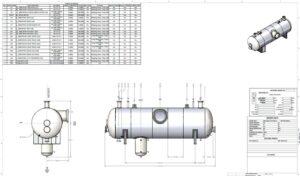

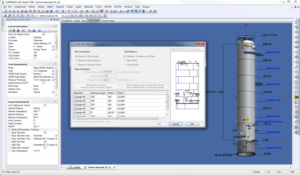

• Mechanical design of pressure vessels and columns per ASME Sec. VIll Div.1, Div.2, EN 13445

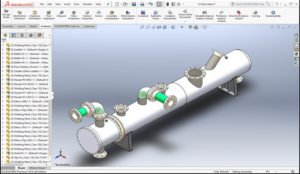

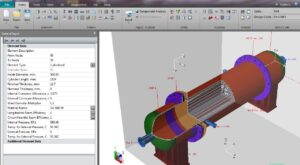

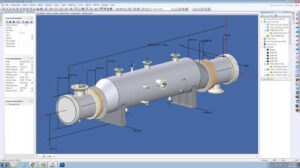

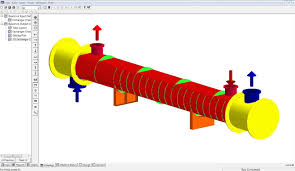

• Mechanical design of Heat Exchangers & Air Coolers

• Thermal design of Heat Exchangers & Air Coolers (TEMA and API 660)

• Mechanical Design of Boilers per ASME Sec I

• Nozzle load Calculations

• Seismic and Wind Design Calculations

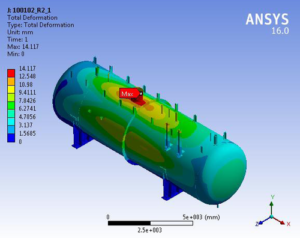

• Fatigue Analysis and FEA (Finite Element Analysis)

• Resistant steels for Lethal services, Hydrogen Service, WetH2S, Amine, etc.

Our staff members are committed to providing our customers the highest quality products. Our seasoned engineering and fabrication teams have obtained the following training and certifications:

RT Level II (Suitable 2014/68/EU)

UT Level II (Suitable 2014/68/EU)

MT Level II (Suitable 2014/68/EU)

PT Level II (Suitable 2014/68/EU)

TEST ACTIVITIES

A large space inside our testing workshops is devoted to testing ACHE products. We also have considerable space outside our workshops to test the largest heat exchangers.

• Radiographic inspection (RT)

• Ultrasonic inspection (UT)

• Magnetic inspection (MT)

• Penetrant test (PT)

• TOFD + PA

• Hydrostatic test

• Pneumatic Test

• Leak test

• Hardness & Mechanical Tests

• Surface Roughness Tests

• Ferrite Check

• Third Party Inspections